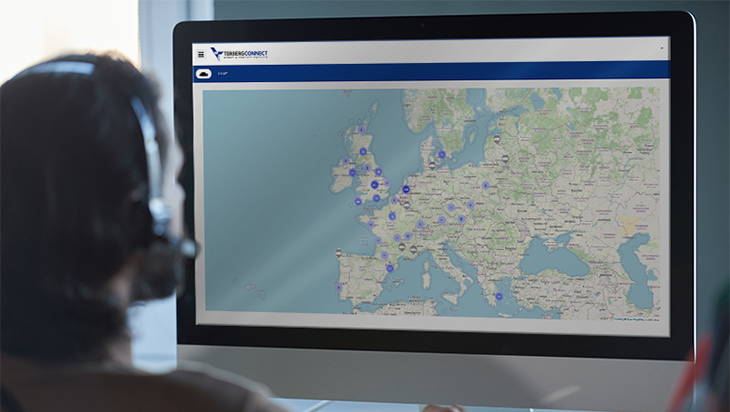

Terberg Connect is a world first in the waste management industry. It utilises industry 4.0 technology to enable two-way remote diagnostics and maintenance operations for all key components of the complete waste collection vehicle.

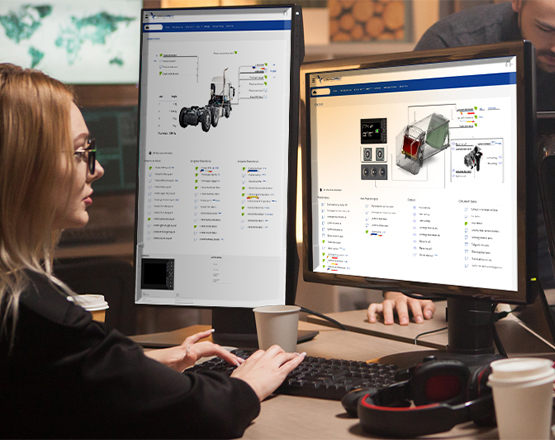

DIGITAL MANAGEMENT OF YOUR COLLECTION VEHICLES, FROM ANYWHERE

Central to how users interact with Terberg Connect is the concept of a ‘digital twin’. We reimagine our physical hardware systems with a virtual on-screen counterpart, accessible via our online interface.